Recent Posts

- KDONAr-3000Y/4000Y/50 (220TPD+2TPD)

- KDONAr-8200/8900/280 (620TPD+12TPD)

- KDONAr-42000/40000/1200 (2700TPD+50TPD)

- KDONAr-84000(1000Y) / 14000(500Y) / 1700

Related Products

Social Media

KDONAr-84000(1000Y) / 14000(500Y) / 1700

|

Operating conditions |

GOX yield (optional LOX yield) |

O2 purity |

GAN yield (optional LIN yield) |

N2 purity |

Argon yield |

Argon purity |

|

Design |

84000Nm3/h or 1000TPD |

99.6% |

14000Nm3/h or 500TPD |

≤2ppm O2 |

1700Nm3/h |

≤2ppm O2 ≤3ppm N2 |

|

Condition 1 |

84000Nm3/h or 1000TPD |

14000Nm3/h or 500TPD |

||||

|

Condition 2 |

73000Nm3/h/ 11000Nm3/h or 1000TPD |

14000Nm3/h or 500TPD |

||||

|

Condition 3 |

65000Nm3/h/ 19000Nm3/h or 1000TPD |

14000Nm3/h or 500TPD |

||||

|

Note:

|

||||||

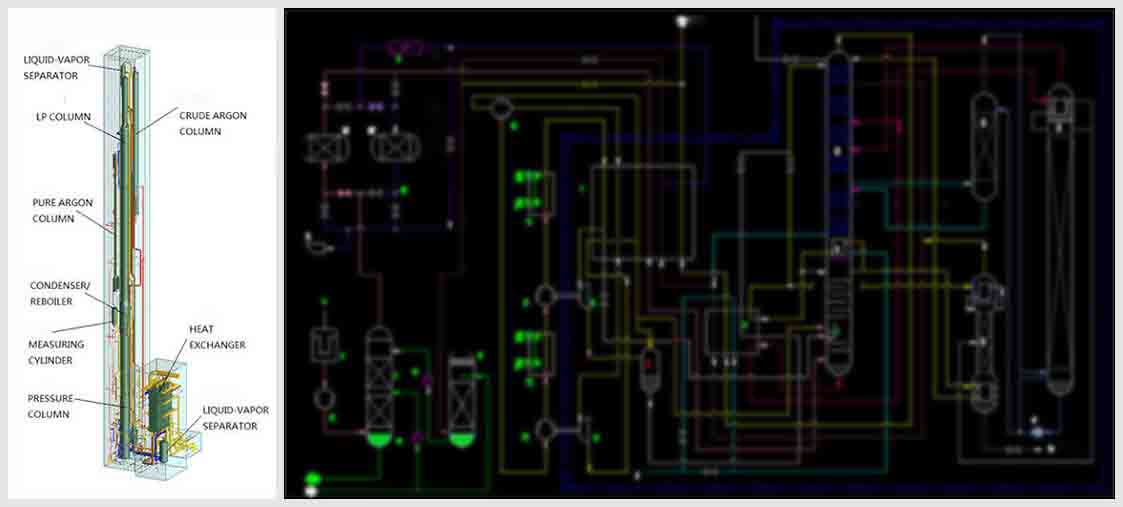

Process brief:

This ASU design is based on the principle of long-term steady operation, low energy consumption, easy management & maintenance and should be of the international advanced technology. It is of an internal compression process of oxygen, with molecular sieve purification system, turbo-expander with booster and upper packing column, using the technology of expanded air entering upper column. The output oxygen and nitrogen pressure can reach as high as 8.5MPa, which meets the diversified requirements of oxygen and nitrogen pressure in the chemical industry. The yield pressure is adjustable up to 8.5 MPa, which satisfies the diversified requirements of industrial gas pressure in the chemical industry.