Recent Posts

- KDONAr-3000Y/4000Y/50 (220TPD+2TPD)

- KDONAr-8200/8900/280 (620TPD+12TPD)

- KDONAr-42000/40000/1200 (2700TPD+50TPD)

- KDONAr-84000(1000Y) / 14000(500Y) / 1700

Related Products

Social Media

KDONAr-8200/8900/280 (620TPD+12TPD)

Project model : KDONAr-8200/8900/280 (620TPD+12TPD)

Location : Qinghai

Year : 2018

Application field : Chemical

ASU specs :

| Operating conditions | Oxygen yield (optional LOX yield) | O2 purity (upgradable) | Gox Pressure | Nitrogen yield (optional LN yield) | Nitrogen purity | Gas Nitrogen Pressure (compressor inlet/outlet) | Argon yield | Argon purity |

| Design | 8200nm3/h or 280TPD (800nm3/h or 27TPD | 99.6%O2 | 8.25 MPa | 8900nm3/h or 265TPD (1600nm3/h or 48TPD) | ≤10PPmO2 | 10kpa /0.9MPa | 280nm3/h or 12TPD | 10kpa /0.9MPa |

| Condition1 | 4300nm3/h or 145TPD (2900nm3/h or 100TPD) | 8900nm3/h or 265TPD | 220nm3/h or 9.5TPD |

Process brief

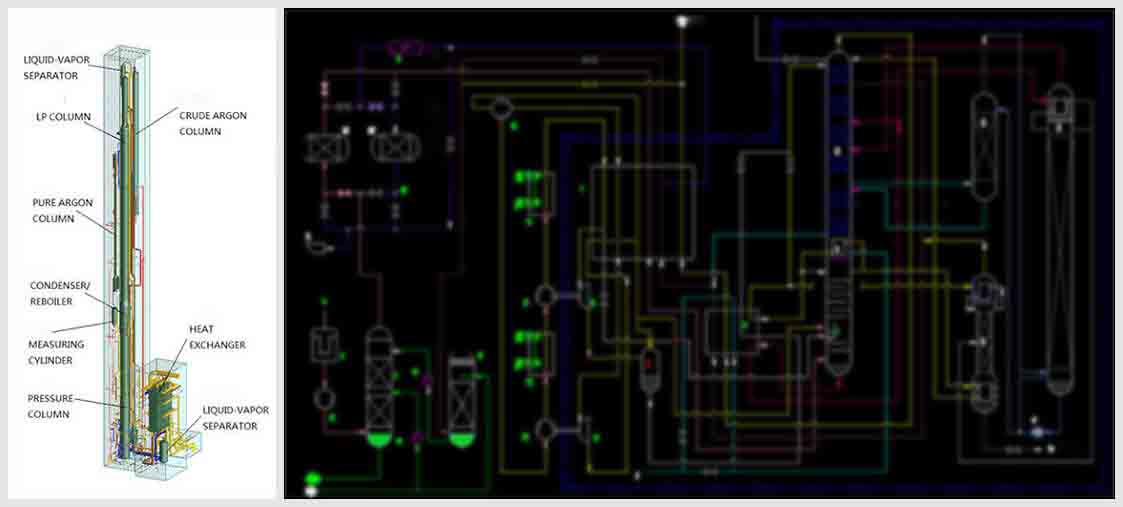

This process is an internal compression air separation process integrating normal temperature molecular sieve adsorption purification, air pressurization booster, high and low-temperature pressurized turbine expander, full distillation of packed fractionation tower to produce argon. And is one of the most advanced internal compression air separation processes in the world.

Main features :

1. Uses liquid pumps to pressurize liquid oxygen, then converse LOX into GOX in the main heat exchanger.

2. Has a higher outlet pressure at the booster end of the expander so it saves more energy.

3. Has a secondary operating condition so the client has option of more fraction of LOX product.